There has been much speculation recently about why Intel’s new Ivy Bridge processors seem to run significantly hotter than the previous-generation Sandy Bridge processors, despite the lowered TDP rating. One proposed explanation is that the thermal interface material between the silicon die and heat spreader was changed: Sandy Bridge processors soldered the heat spreader to the silicon, while Ivy Bridge processors use some silicone-like adhesive compound.

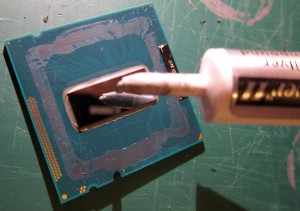

To test this, I’m going to pop off the heat spreader, then replace the thermal interface material with Arctic Silver II. I don’t expect it will be as good as solder, but it’s a reasonable approximation of what can be reasonably achieved by modding.

Tools

- Razor blade (Thinner is better. Thick may deform package substrate.)

- Hammer

Procedure

Lightly hammer razor blade in between substrate and heat spreader, being careful to keep blade near-parallel to the chip to avoid cutting into the substrate. Also note where the die is located to cut all adhesive without cutting into the die. The heat spreader is much harder than the substrate, and using a blade that is too thick will warp the substrate.

I replaced the existing thermal material with Arctic Silver II. I also cleaned off the adhesive so that the heat spreader pressure is applied entirely onto the die.

Test Environment

- Intel stock heat sink and fan

- Stock phase-change thermal paste that came on the heat sink

- Ambient temperature: 26 °C

- GA-Z77M-D3H-MVP motherboard (with no VCore adjustments)

Observations

- The thermal interface material resembles silicone with filler. It does not melt at 200 °C.

Measurements

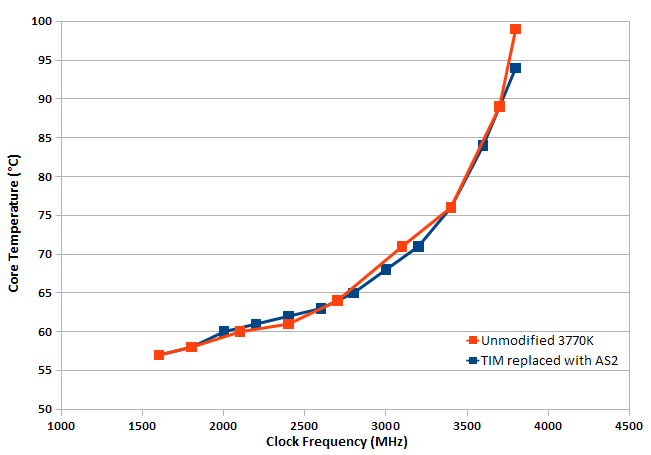

| Frequency (MHz) |

Vcore | Unmodified (°C) |

Modified (°C) |

|---|---|---|---|

| 1600 | 0.96 | 57 | 57 |

| 1800 | 0.96 | 58 | 58 |

| 2000 | 0.96 | – | 60 |

| 2100 | 0.96 | 60 | – |

| 2200 | 0.96 | – | 61 |

| 2400 | 0.98 | 61 | 62 |

| 2600 | 0.96 | – | 63 |

| 2700 | 0.97 | 64 | – |

| 2800 | 0.96 | – | 65 |

| 3000 | 0.98 | – | 68 |

| 3100 | 1.00 | 71 | – |

| 3200 | 1.01 | – | 71 |

| 3400 | 1.04 | 76 | 76 |

| 3600 | 1.09 | – | 84 |

| 3700 | 1.13 | 89 | – |

| 3800 | 1.15 | 99 | 94 |

There seems to be no difference in temperature (except the final data point) between the unmodified CPU and modified with the thermal interface material replaced with Arctic Silver II. The final data point is 3.8 GHz, 1.15 Vcore (115 W CPU power), with 99 °C before and 94 °C after modification. There is some uncertainty in the measured values, so the temperature improvement is something like (5±2) °C.

The measurements were taken with CPU fan PWM enabled as default, which may contribute to the lower-speed data points having similar temperatures before and after the modification. Unfortunately, I didn’t take fan RPM measurements, so I don’t know how much impact PWM would have. There should be no impact on the 3.8 GHz data point because the fan should be at full speed for both test cases anyway.

Conclusion

Changing the standard thermal interface material to Arctic Silver II gains around 5 °C at 3.8 GHz (115 W), suggesting an improvement in thermal resistance of around 0.04 °C/W. Since the stock cooling system gets around 0.6 °C/W, this is not really a significant improvement. The improvement would be relatively more significant when using a custom cooling system with a much lower thermal resistance.

It seems like the impact of switching from solder to silicone thermal interface material isn’t high enough to explain the increased temperature of Ivy Bridge chips…

I won’t be letting a hammer anywhere near my expensive new Ivy Bridge.Brave of you to give it a go though – thanks.

I see absolutely no point in testing modified IHS with Intel stock cooler. 😉

Perhaps unconventional, but when you’re building systems with budget, space, and noise constraints (like these), every degree counts. 🙂